Webinar - There’s no sugar-coating it: In coatings applications, poorly ground rolls will cost you money

Published on May 25, 2021

There’s no sugar-coating it: In coatings applications, poorly ground rolls will cost you money

Variation is a profit killer. Especially when it comes to coatings applications.

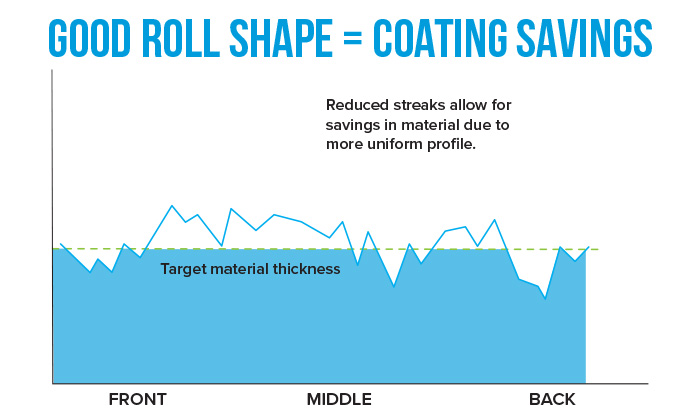

Whether you’re coating online on a paper machine or coating offline on various substrates such as metal, plastic, or again paper, variation will prevent you from obtaining a uniform coat weight and force you to use more coating material. Which, in the end, costs you more money. Reducing variation in your coatings process is also key to more consistent product, reducing the number of product returns and retaining happier customers — all of which contribute to profitability, as well.

Obviously, you should take advantage of any opportunity you have in your processes to reduce variation. One of the most important actions you can take is investing in proper roll grinding and servicing. In our latest webinar, “Precision Coating Demands Precision Rolls for Optimum Performance,” we look at how your rolls may be forcing you to use more coating than you need to — and how you can eliminate this costly situation.

We discuss how rolls ground to exact tolerances drive optimization in your process — as well as the costly results that you incur when they are not. We also explain how costly variation manifests itself in machine-direction variation and cross-direction variation and how overcompensating to make up for these variations results in wasteful excess coating.

Most importantly, we present how you can avoid material waste through proper roll grinding and service. Learn the importance of proper roll roundness and concentricity. See why roll tolerances, roll shape and roll mechanical servicing are all very critical to your coating operations. Understand the impact they have on machine- and cross-direction variation. And get input from your service provider on what you can do to avoid imprecise rolls. You’ll discover why rolls should never be ground on their bearings, questions to ask your provider, determine if you’re getting a return on your roll investment and much more useful advice. All based on 50+ years of experience.

Finally, you’ll hear why rolls that begin closer to perfectly round have a longer run life and deliver a more consistent product throughout the life of that roll — another way to introduce greater profitability into your coatings process. The webinar gives a detailed explanation as to how rolls ground and serviced by PRG can last up to 2 ½ times longer than rolls from other providers.

Get a new perspective on your coatings process and the actions you can take with your rolls for improved profitability. Watch our “Precision Coating Demands Precision Rolls for Optimum Performance” webinar today. Click here to download the webinar or watch it below.